Ship Passengers arriving in San Francisco: 1800s

Peter Donahue: The Union Works

Born in Glasgow, Scotland

Died 1885, San Francisco, California

|

Peter and his brothers had spent their younger childhood days toiling in the Glasgow sweatshops of that period.

Peter was eleven in 1833 when the family sailed for America. A few years later he was apprenticed to the Union Iron Works of Paterson, New Jersey as a student machinist. His two brothers were bound to the same concern, James learning boiler making and Michael becoming a molder. It was this firm?s name which they later applied to their own enterprise.

In 1845 Peter was employed on the construction of a gunboat for Peru and sailed aboard her on her maiden voyage to South America. In 1847, he signed on as assistant engineer of the gunboat; it was the first American-built steamship to navigate the Strait of Magellan.

Peter Donahue was in Peru when news came of California's gold discoveries. He purchased a ticket on the SS Oregon when she was coming around the Horn in 1849; he contracted malaria enroute and remained in Panama until the Oregon returned.

On the Oregon's return, Donahue made $1,000 by overseeing the repair of its boilers. He then traveled on the ship as its engineer, reaching San Francisco in June 1849. In Panama, he had bought a quantity of onions, which he sold in San Francisco to a dealer, who turned around and sold them for $1 each.?

In 1849, Donahue's brothers, James and Michael were in San Francisco. After a short stint in the gold fields, they opened a blacksmith shop in a tent. They then opened California's first iron foundry south of Market.

In 1852, Donahue applied for a franchise to erect a gasworks, lay the pipes and install street lamps. He would charge the city 32.5 cents per lamp per night. The Donahues got the franchise, however they still didn't have a gasworks, nor the money or know-how to build one; however, they organized the San Francisco Gas Company in 1852, authorizing the sale of $150,000 in stock.

In 1853, Peter Donahue became the sole-owner and renamed the foundry the Union Iron Works.

Donahue's Iron Foundry

March 6, 1857, California Farmer and Journal of Useful Sciences

Donahue's Iron Foundry

How very few among the great masses in our community are aware of the stupendous enterprises that are being carried on in our midst, and how few are conversant with the immense amount of money that is daily and weekly paid to the mechanics of our city by some of the proprietors of our enterprising manufactories.

Recently, we were kindly invited to visit the new foundry of Peter Donahue, Esq.. on First street, and we confess we were surprised to note the extent of the enterprises connected with this immense establishment. Mr. Donahue has recently erected a large and substantial fire-proof building, four stories high; the main buildings and the adjoining ones covering an entire block of ground.

The first floor of the main building is occupied for the heavy work -- here are castings of all kinds, some of them of the greatest magnitude. We saw a very powerful hydraulic press of 7,000 pounds weight, made for Theo. Welzel's candle factory, capable of working a pressure of 300 tons. We also saw a beautiful press, made for Col. Harasky, for his melting and refining establishment, which we learn is nearly completed. We examined a double engine, made to order, of great power, and perfect finish. This engine was making for Don Francisca Bustamente, of Mazatlan, to work rich, extensive mines which had been long idle. These mines had already been worked 1,000 feet. The engines were of powerful make, so as to secure their object, and would cost in the vicinity of $25,000.

To show the power of this foundry, we ascertained that castings could be had of fifteen or twenty ton pieces. A boiler for the steam tug Resolute was being made, and it is as fine a piece of work as was ever seen, costing some $7.000. We entered the " infernal oven," where the sand is dried for castings. It was a comfortable place on a cold day.

The work for quartz milling is done at Mr. Donahue's, to a large extent, and we learn that this kind of work is rapidly increasing from every part of the quartz mining districts.

The second story of the foundry is used as a carpenter's shop ; and here are made innumerable patterns of the various castings of this foundry -- from the most minute to the most gigantic.

The third and upper stories are used as the pattern rooms. They make a perfect museum; and here all that skill and ingenuity could devise, in form or size, can be found. Some estimate can be had of the extent of it, when we say that the collections of the patterns of this foundry are worth over $20.000.

Those powerful machines of Messrs. Stillnian, Allen & Co., of New York, lor riveting, punching, and heavy shears that will cut up iron plate as easy as a child will cut pasteboard, are used at these works. All the machinery of these extensive works is moved by a double engine of thirty horse power, which works to perfection . . .

A Word for Farmers and Grain Growers.

Leroy's mower attracted our notice, and we took some time to examine this implement now passing to some still greater improvements. Mr. Donahue has purchased of the inventor the patent right for the U. S., and intends to make it one of the best implements that can be found. The great desideratum sought for, and which is to be perfected in this machine, is a new power of conveying a lateral motion to the knives. This is done by a serpentine groove in the cam-wheel, which oscillates rapidly and perfectly, or so well as to cut every blade of grass or grain heads?for the intention of Mr. Donahue is to make it a mower and reaper, and to make them durable. One great objection to many of the implements is, they are not strong enough for the heavy work required here. In these, particular attention will be given to the pivot joint and lower joint, where it connects with the knives, to make them so strong and firm as not to get out of order, and to work so perfectly as to save friction, and thus work smoothly and easy. These important features the present proprietor feels confident can be attained?and he will have the machines ready for sale the present season, for $600 to $750 each, of the largest and best size.

This is an important fact?for all the machinery that can be manufactured here saves so much to tho wealth of our State, and gives employment to our own mechanics, which should be tho aim of all who desire the prosperity of California. And Mr. Donahue is certainly doing a noble share? for we learn that about one hundred men are now employed in these works, requiring a very handsome sum of money weekly. The good of such enterprises is told in a few words ?such men are true public benefactors. During the time given to this examination we were exceedingly and repeatedly gratified at the evidences we saw of the skill of our California mechanics ?and, for the pleasure we enjoyed, we were indebted to Mr. Lightner, the able superintendant, who most courteously conducted us over the whole establishment, so explaining to us the several plans of labor as to make it doubly interesting, for which we return our kindest thanks.

November 30, 1857, Sacramento Daily Union

Sacramento, California

|

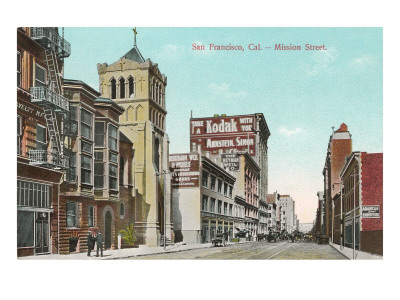

The Union Iron Works, located at the northeast corner of Mission and First streets, is a monument of the enterprise and perseverance of Peter Donahue, the sole proprietor. Mr. Donahue, together with his brothers, came to California early in the year 1849 and immediately started a small blacksmith's and machine shop on the lot now occupied by Wright's building. Of course the operations conducted by these gentlemen, were at that time upon a very limited scale, but early in the year 1850 the works were transferred to the location of the present foundry, where the business was carried on until the year 1856, in buildings which, though more commodious than the first, were entirely inadequate for the rapidly increasing business of the establishment. In 1850, the present structure, a description of which will be presented in the proper place, was erected; and San Franciscans may now boast of one of the most complete foundries west of the State of Ohio, being in operation in their city.

During the past six months, Mr. Donahue has furnished employment to an average of about eighty hands; the average for the last four years, will not vary much from one hundred. When a quantity of machinery (hereafter to be spoken of) shall have been erected, which it will be, it is expected within sixty days, continuous work will be supplied for at least one hundred and fifty men. As workmen, in an establishment of this kind, receive liberal wages, it will be readily understood that the aggregate amount expended by Mr. Donahue, for labor, must be very large. We are informed that he has paid out in this way, during four years, an average amount of from $150,000 to $200,000 per annum -- or two-thirds of the entire expenses of the concern.

It may be considered as indicative of the growing prosperity of California, that the facilities of this establishment are to be immediately increased. It will be remembered that our description of the San Francisco Sugar Refinery mentioned certain additions to, and improvements in, that manufactory; this spontaneous and unconnected action upon the part of gentlemen engaged in two widely different branches of business, may reasonably be called significant.

With regard to the health of those employed in foundries, the brawny arms and stalwart chests of the operatives we saw while inspecting the Union Iron Works, sufficiently show the manly and invigorating nature of the work they perform. There is surely no feminine or enervating labor about a foundry. Even farming can scarcely be more conductive to rugged health.

The main lot is 137-1/2 feet square fronting on First and Mission streets; in addition to this, there are two other lots, 40 feet by 8O each, and one fronting on Fremont street, the other on Mission street. The whole grounds embrace five full lots.

The Foundry is a substantial brick building, one story in height? 50 feet front by 54 feet deep.

The Finishing Shop, a solid brick structure, four stories in height, fronts on First street 87-1/2 feet. Its depth is 40 feet. The Blacksmith Shop in the rear is 50 feet square.

The Boiler Shop is a wooden building, 120 feet by 3O; this excludes a large tower tor the steam-riveting machine.

In addition to these buildings, there is a house in the rear of the workshops, which is divided into store rooms and offices.

The machinery and principal implements connected with the establishment, are as follows; In the center of the Foundry is a substantial crane, used for lifting heavy pieces of casting from one part of the building to another. As much as five tons weight of iron has been lifted by this crane, at once; it is supposed to be capable of sustaining seven or eight tons. There are also in the Foundry two cupola furnaces, for melting iron. As many as four tons have been melted within an hour. There are are one cupola and two air furnaces for inciting brass. These cupola furnaces are furnished with blasts by a large Demphel fan. There is a Blacking Mill in one corner of the Foundry, driven by a belt from the machinery in the Finishing Shop.

The lower story of the Finishing Shop contains the engines and boilers, which supply the entire establishment with steam power. There are two plain high pressure engines, each of fifteen horse power, and locomotive boilers. There is a quantity of fine machinery upon the way between New York and this port, per ship Martha, which it is intended to put up in the first story. This machinery embraces a number of articles of value, which will save a considerable amount of manual labor. Among them are ? a large radical drill, a large compound planer, and a shaping machine. It is expected that this machinery will be in operation within sixty days.

The second story of the Finishing Shop contains one large lathe and two upright drills; together with all the necessary vices and benches for fitting up of work. It gives some idea of the power and perfection of machinery to see one of the planers taking off a shaving of iron of the thickness of one-eight of an inch, and leaving the surface as smooth and even as the finest planed board. The manner in which the piece of iron, of whatever size or pattern it may be, is kept continually advancing, as the planing machine cuts away ? by the use of the screw as a mechanical power ? is also quite interesting to unsophisticated persons.

The third story of this building is the Pattern Shop of the establishment Here, whenever a piece of work is ordered, the wooden patterns necessary before the casting can be proceeded with, are constructed. The accuracy with which patterns have to be made, and the great amount of work in cutting them out and finishing them, render them very expensive. We were shown a number, which we should have imagined to be scarcely of any value ? tiny were worth from ten to thirty dollars each. In this story there are two lathes aid a jig saw for the exclusive use of the Pattern Shop.

The fourth and highest story is used exclusively as a store room for patterns. It contains unquestionably the most complete collection in the State, and one which would do credit to any manufacturing establishment ? particularly in gearing patterns. The collection embraces not only the accumulated stock of the Union Iron Works, but also the stock which formerly belonged to the Alta Foundry. The patterns are of every conceivable size, shape and finish : there are patterns of steam engines, machinery for quartz, saw and grist mills, and for gas work. There are over one hundred patterns of spur, bevel and mitre wheels alone.

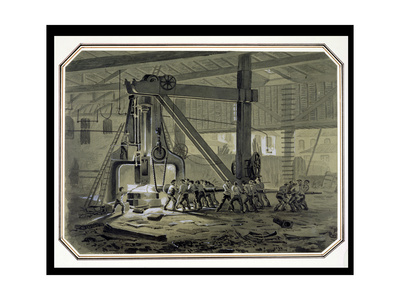

The tools in the Boiler Shop are said to be the finest in the State. In this shop is a line of shafting driven by the machinery in the Finishing Shop; large steam punches; shears, and a riveting machine. The shears are from the largest pattern used at the Novelty Iron Works, New York, and are even made extra strong. They are capable of cutting any sized boiler plate which has ever been manufactured, and are considered by those competent to judge, the greatest labor saving machinery of the kind west of -New York. Indeed to see them cut a strip of iron half or three quarters of an inch in thickness, in two, as quickly and neatly as a lady would sever a silken thread, with her delicate scissors, about fills up a man's estimate of strength.

There are six forges in the Blacksmith's Shop, and a large steam hammer for heavy forging has just been completed and is about to be erected in this shop.

|

We propose to give a description, which may give a general idea of the manner of casting and finishing machinery. We will select the cylinder of a steamboat. In the first place, a draught the shape, size, etc., of the cylinder has to be prepared from this draught, the pattern makers construct the pattern, which is passed into the foundry, where the moulds are prepared and the melted metal poured into them.

There are so many varieties of preparation for casting ? so many adaptations of the shape of the moulds to that of the castings ? sometimes hollow ? that it would be absolutely impossible, within our limits, to describe even a tithe of them. When a solid piece of casting is to be done, the patterns, which are made in halves, are imbedded in moist sand, surrounded by a frame of wood. The sand is pounded until it is perfectly solid, when the patterns are taken out, and the two halves being placed together, the space surrounded by the sand is of the precise shape and size of the casting required. A large plug, reaching to the mould, is now drawn out and the metal poured in, when, after it cools, the casting is completed. There are also a number of small holes pricked in the sand to allow the emission of gas from the mould when the boiling metal is poured in. Very few failures take place in casting.

But to return to the cylinder. After the casting, it is taken into the yard and cleaned ; it is then placed in the boring mill in the finishing shop, and after having" been bored, drilled and fitted, it is completed.

The modus operandi of making boilers is briefly the sheets of iron are laid out by the foreman and punched; they are then sheared by machinery, bent in large rollers, and riveted by the steam riveting machine. Subsequently they are chipped, caulked, and put together by hand. ? San Francisco Herald, November'25th.

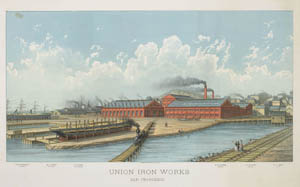

Union Iron Works (Shipyard opened 1884)

After years as the premiere producer of mining, railroad, agricultural and locomotive machinery in California, Union Iron Works, led by I. M. Scott, entered the ship building business and relocated to an area known as Scotch Hill (now Portrero Hill) in the 1800s due to the Scottish boat builders and iron workers who lived above the Union Iron Works. The first?U.S.S. San Francisco?was a cruiser built at the Union Iron Works. She was commissioned in 1890 and later converted to a mine layer called the?Yosemite.

Donahue originally constructed the Tiburon Railroad-Ferry Museum building in 1884 as the terminal depot. It was then surrounded by train sheds, a round house, machine shops, offices, and the ferry slip with a wharf running down both sides. In all, the huge, deep water complex encompassed more than 60 acres, with 50 buildings. The museum alone now graces the Paradise Drive waterfront, downstairs depicting the old passenger terminal station for both trains and ferries, while the upstairs recreates the home of the railroad agent William Bent and his family. This is one of two surviving dual-use terminals nation-wide. The museum houses a working model of the old Tiburon rail yard, and reveals how the local working class lived upstairs. Its also fun to wander some of the old neighborhoods, like nearby Old Tiburon, to get a feel for the old days. Tiburon literally sprung up when the train arrived. Some of the oldest homes date back to this era. Other neighborhoods with original homes include Belvedere Street, Italian Row, and Community Road.

In 1885, the Union Iron Works launched the first steel hulled ship on the west coast, the?Arago, built with steel from the Pacific Rolling Mills. In 1886, UIW was awarded a one million dollar contract to build a Naval cruiser, the?Charleston, which they completed in eighteen months. From the completion of the Arago?in 1884 to 1902, Union Iron Works built seventy-five marine vessels, including two of the most famous vessels of the Spanish American war, the?Olympia?and the?Oregon.

Daily Alta California,?February 2, 1886

THE NEW STEAMSHIP For the Oceanic Company May Perhaps be Built at this Port.?

In regard to the proposed construction of a 4000-ton steamship by the Oceanic Company, it is not settled that Cramp of Philadelphia, who built the?Alameda?and?Mariposa, will get the contract, but he will obtain it only on condition that he underbids other American builders. The Union Iron Works of this city may get the contract. In speaking of the probability of the work being done on this coast, Claus Spreckels expressed a decided preference for spending the sum (roughly estimated at $600,000) at the shipyards of San Francisco. The managers of the Union Iron Works will have a field of equal competition for the contract, with several points in their favor, and if it is found that the work can be done successfully here, Eastern builders will not get the work. In making estimates the officers of the company figure that they could save $60,000 by having the ship built in the yards of Scotland, but they hold fast to the conviction that ship-building enterprises in the United States should be promoted to every degree possible by our own citizens, and also fostered by Congress. In naming ships of the Oceanic fleet it was decided when the first vessel was built to name all the steamers in the line in honor of counties of California ending with the letter "a," and it is understood that this rule will be adhered to. New iron ships will be constructed from time to time, as the growth of commerce demands.

Copyright ~ 1998-2018.

Copyright ~ 1998-2018.